Science fiction author Arthur C. Clarke famously said that “any technology sufficiently advanced would be indistinguishable from magic.” One of the more exciting new developments to hit the consumer market in recent years is 3D printing. And while the concept of going from a digital “blueprint” of a model to a three dimensional object you can hold in your hand might appear to have more than a little magic involved, it all makes sense once you understand the technology involved. How do 3D printers work? Read on to find out.

How Do 3D Printers Work?

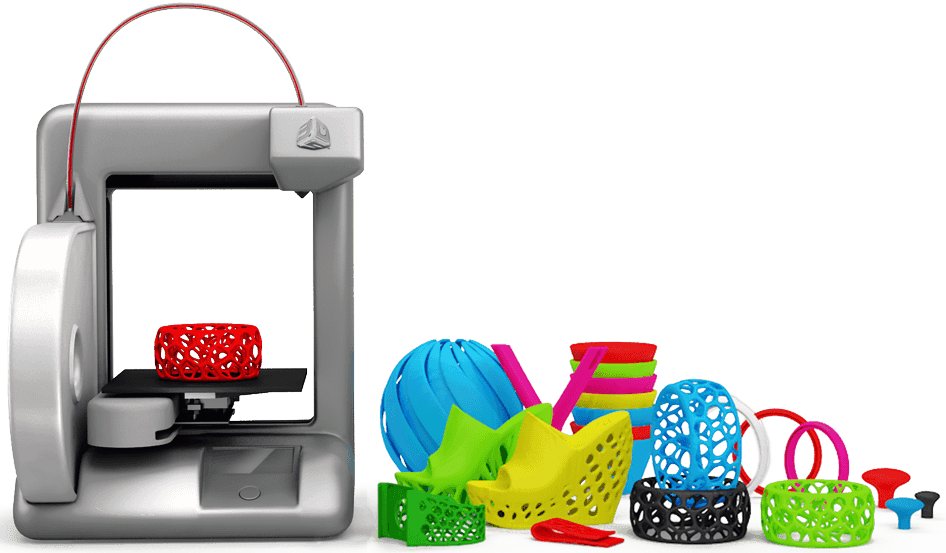

The 3D printer shares more than a passing resemblance to an inkjet printer. Instead of a print nozzle moving back and forth and spraying liquid ink on paper that’s fed through the printer, a 3D printer’s “print nozzle” and platform move in three dimensions (left to right, forward and back, up and down) and instead of spraying drops of liquid ink, it’s laying down a layer of melted plastic.

There are differences —instead of a print nozzle, you have a high temperature extruder; most consumer-level 3D printers use only one (or sometimes a few) colours at a time, the extruder is usually visible instead of hidden with a plastic case and it can take a few hours to print a 3D model instead of the seconds it takes to print a page— but once you see a 3D printer in action, you’ll quickly grasp the concept.

Here’s a short time lapse video clip I shot of a 3D printer I had the opportunity to try out. I find it fascinating to watch the extruder zipping around as the model (a rook from a chess set) slowly rises.

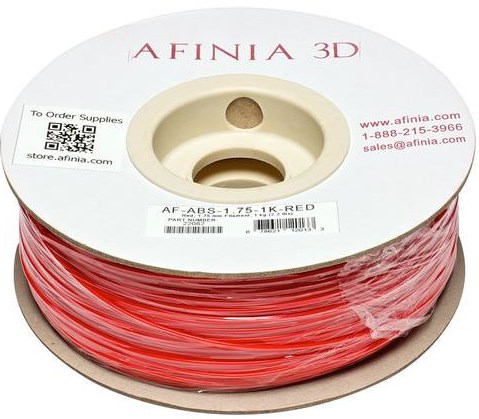

Instead of ink or toner, a 3D printer uses plastic. Most printers can use two different types: PLA (Polylactic Acid) or ABS (acrylonitrile butadiene styrene) —you can see why the acronyms are more popular…

Both take the form of spools of plastic filament offered in a variety of colours. Some 3D printers put those spools inside a print cartridge, for easier loading. Thread the plastic filament into a feeder, gears pull it to the extruder and from there it’s heated and laid down as a melted filament (usually around 1/10 of a mm in thickness). The plastic quickly adheres to the previous layer, flows into it and hardens to form a solid object.

Both take the form of spools of plastic filament offered in a variety of colours. Some 3D printers put those spools inside a print cartridge, for easier loading. Thread the plastic filament into a feeder, gears pull it to the extruder and from there it’s heated and laid down as a melted filament (usually around 1/10 of a mm in thickness). The plastic quickly adheres to the previous layer, flows into it and hardens to form a solid object.

The print platform of the 3D printer may be heated to prevent the base layer of plastic from moving around, or (like the version I used), you might spread a thin layer of adhesive on the platform to secure the model.

How do 3D printers work when it comes to finishing the model? They don’t. This is where you, the human, come in. The 3D model that’s printed may have a few rough edges and support structures. Depending on the model, they may need to be sanded off to finish the model and make it perfectly smooth.

How Does the 3D Printer Know What to Print?

3D printers can’t print without instructions and in this case, it’s a digital file that’s essentially a 3D blueprint of the object to be printed. These files are usually in the STL format and can be viewed (and created) with 3D software included with most 3D printers. Upload the STL file to the printer via USB, Wi-Fi or thumb drive (depending on the printer) and it does the rest. You can find 3D printer files online and printer manufacturers will include a selection of them for free.

3D printers can’t print without instructions and in this case, it’s a digital file that’s essentially a 3D blueprint of the object to be printed. These files are usually in the STL format and can be viewed (and created) with 3D software included with most 3D printers. Upload the STL file to the printer via USB, Wi-Fi or thumb drive (depending on the printer) and it does the rest. You can find 3D printer files online and printer manufacturers will include a selection of them for free.

The latest development in this area is the release of 3D scanners that automate the process of duplicating an object by scanning and generating an STL file, making a 3D scanner/3D printer combo the three dimensional equivalent of a photocopier.

What Will You Use a 3D Printer For?

Many people had a hard time figuring out why they would ever want an inkjet or laser printer for their home. But look what happened there. Photo printing labs? Pretty much gone the way of the dinosaur. Instead, digital cameras combined with home inkjet printers mean you can snap a photo and print off a copy on demand. School assignments have never looked better thanks to those home printers. Now, it’s hard to find a home that doesn’t have either an inkjet printer or a laser printer —or both.

In the month that I spent with a 3D printer in the house, I quickly discovered that this technology actually has many applications outside of manufacturing.

Here are just a few examples:

Business

Business

You don’t have to be a multinational manufacturer to put a 3D printer to work. Small businesses can use 3D printers to quickly whip up prototypes of everything from parts to models of buildings. There’s also a growing use of the printers to make promotional and marketing material that stands out from the crowd such as 3D plastic business cards, embossed coins and 3D printed logos.

Educational

Got kids? Having a 3D printer can give them an edge when it comes to education. There’s a growing library of digital plans for educational models like molecules, gears and body parts. Instead of just reading about how these work and viewing pictures, being able to print out the pieces and assemble a working model brings many educational concepts to life.

Practical

One of the most exciting aspects to being able to 3D print something on demand is the practical applications of the technology. For example, have you lost a key piece of a building set and can’t find a replacement brick? There’s probably a digital file posted online that would let you print the piece yourself. Hobby communities have already released STL files that let you use a 3D printer to create something that never existed before —bridge pieces so you can combine previously incompatible building sets.

3D printed iPhone cases made with Cube 3D printers

There’s a growing online collection of 3D printable replacement parts for old appliances (obviously, metal pieces can’t be replaced, but plastic gears, clips and covers can often be replaced with 3D printed versions) —this is great news for people who need just one part for a dishwasher that’s 20 years old. And if there’s a product you own that could be made just a little bit better through the addition of a customized part, most consumer 3D printers include design software so you can create that component and print it out yourself. For example, this 3D printed 360 Heroes camera mount that combines 12 Go Pro Hero cameras for filming 360-degree video.

There’s a growing online collection of 3D printable replacement parts for old appliances (obviously, metal pieces can’t be replaced, but plastic gears, clips and covers can often be replaced with 3D printed versions) —this is great news for people who need just one part for a dishwasher that’s 20 years old. And if there’s a product you own that could be made just a little bit better through the addition of a customized part, most consumer 3D printers include design software so you can create that component and print it out yourself. For example, this 3D printed 360 Heroes camera mount that combines 12 Go Pro Hero cameras for filming 360-degree video.

Other companies are getting into the practical aspects of 3D printing too. For example, last year Nokia (maker of the Lumia line of Windows smartphones), released the Lumia 820. This was a smartphone with replaceable body shells. What made the Lumia 820 special was Nokia’s decision to publish the plans that let anyone with a 3D printer print their own customized shells that would fit the Lumia 820 exactly. There are also plans online for hundreds of different 3D printable protective cases for iPhones, Galaxy S4s and other smartphones.

Fun

Of course, this is one of the cooler uses of 3D printers, and one of the first things anyone does when they unbox their new high tech machine.

The printer I used included files to print extremely detailed 3D chess pieces, including a rook that had incredible brick detail and a staircase winding down its interior. Use your imagination and you can create virtually any customized chess set you could want. Gamers have already made extensive use of 3D printers to create their own figurines.

The printer I used included files to print extremely detailed 3D chess pieces, including a rook that had incredible brick detail and a staircase winding down its interior. Use your imagination and you can create virtually any customized chess set you could want. Gamers have already made extensive use of 3D printers to create their own figurines.

There are literally thousands of plans available for printing small toys on demand, a great option to have when someone suddenly develops an interest in dinosaurs, robots or spaceships.

Then there are the artistic applications. The web is full of photos of artistic objects that simply wouldn’t be possible without a 3D printer including elaborate vases, intricate jewellery and unique sculptures. Once a work of art like this has been created, using the 3D blueprint and a 3D printer, you can make as many exact duplicate copies as you want —one for each of your friends, each in a different colour! Or a sall business opportunity…

I printed a few bracelets (the files were included with the test 3D printer) that my daughter took to school and shared with her friends. They were a hit.

3D printed watchstraps from NOOKA

It’s Not Just Plastic

As 3D printing has become more sophisticated, additional uses have been found for the technology.

Being able to print complex components using metal instead of plastic has led to 3D printers becoming more common on production floors. A 3D printed metal piece is as strong as one made through traditional methods (sometimes stronger because it’s a single piece) and 3D printers make it easier for manufacturers to make just a few components as needed —just load up the software and fire up the 3D printer. Boing, for example, currently makes 300 different small parts for its airplanes using 3D printers.

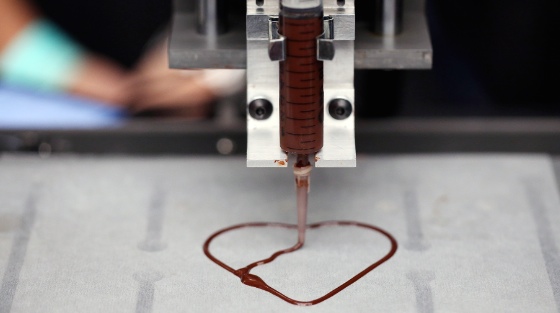

CNN says hershey is working on its own chocolate 3D printer

3D printers are also showing up in the food industry, where they can create elaborate chocolate creations (yes, there are 3D printers that use chocolate instead of plastic filament) and companies are hard at work with prototypes that print artificial meat.

Human prosthetics are now being 3D printed and replacement organs are on the horizon.

Coming Soon

Believe it or not, 3D printers have been around for 25 years. But it’s only in the past several years that they’ve become compact enough and affordable enough for home use. And while 3D printers from only two or three years ago featured plywood cases and had to be assembled before use, today’s models look like high tech home appliances and are easier to use than ever.

And with every passing day, it seems as though people are finding new applications for these amazing machines.

When you see a 3D printer on store shelves, now you know how it works and just a few of the ways you can use it —now might just be the time to pick one up and begin exploring what’s possible. They may be relatively rare in 2014, but it seems likely that 3D printers will follow the same trajectory as inkjet and laser printers, quickly finding their way into every home.